Manufacturing Companies for Instapak 901 - polyurethane foam injection molding machine – Zhuangzhi

Manufacturing Companies for Instapak 901 - polyurethane foam injection molding machine – Zhuangzhi Detail:

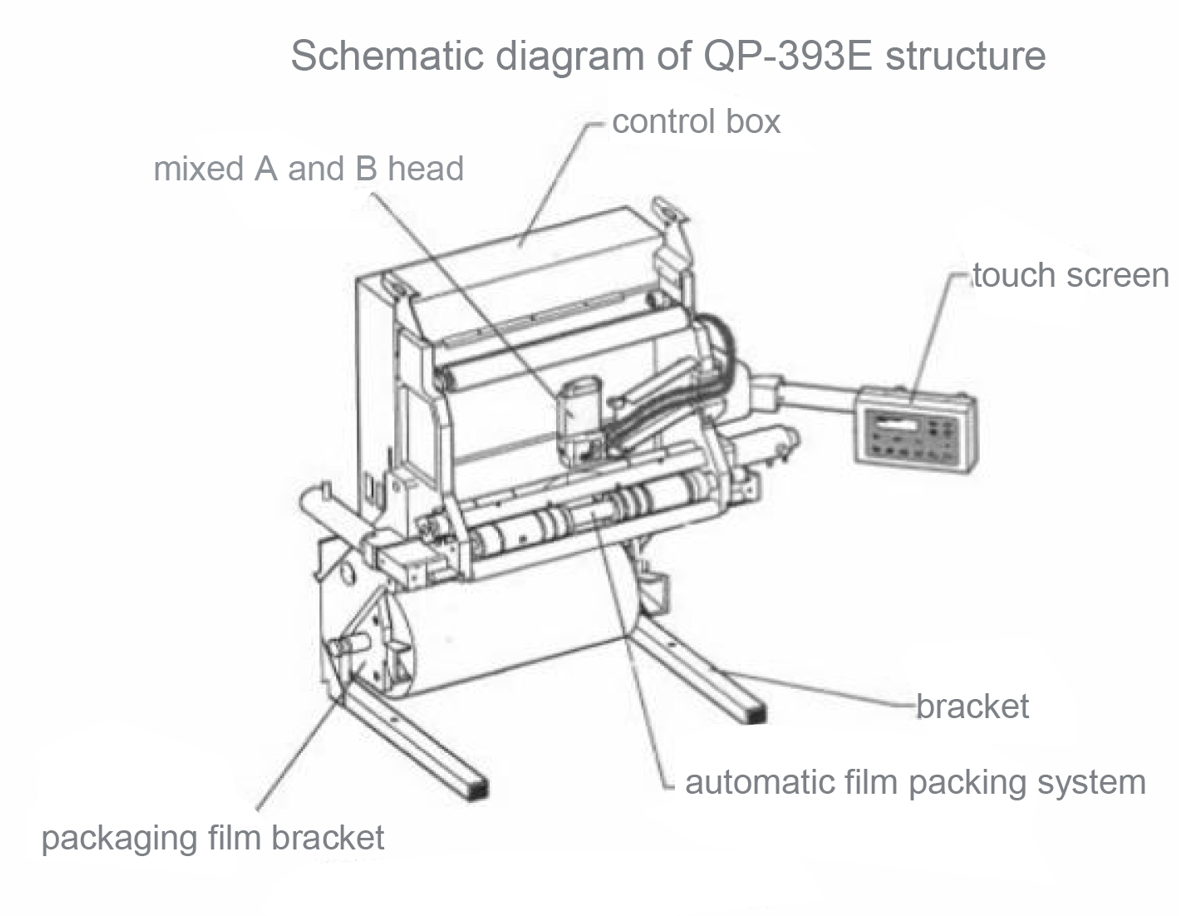

Polyurethane foam packaging automatic bagging system portable foam-in-place machine(393E)

Expanding foam packaging system is easy to use and can make anyone a packaging expert in just a few minutes.

foam in place has many uses and can be used to pack product packages of almost any shape,

size and weight. Foamed on site, fast packaging, it takes a few seconds to customize protective

packaging pads for your products, saving space compared with traditional packaging materials,

taking up less storage space, reducing material handling costs. Convenient and practical,

no matter the size of the company can easily use instant foam bag packaging

Packaging materials :

foam in place packaging materials using two foaming and foam pack machine equipment, the packaging materials

and foaming agent in a certain proportion mixed into the gap between the container and the product, after a short time, the material

will automatically foaming expansion, fill the whole space, in the product around the formation of buffer liner. In order to prevent

the heat and moisture of rapid foaming to the adverse effects of the product, avoid direct contact between the material and

the product surface, but also with a certain strength of plastic bag as the outer envelope of the foam body.

Features

1.LCD touch screen, with the touch of a button ,your can adjust the proper

Bag length and amount of the QuickPack foam.

2. English and Chinese menu, easy for operation.

3. Clean, faster, versatile and economically packaging solution

| Item | Auto Pu foam making machine | ||||||||||

| Density | 5.1KG/M3,10KG/M3,17KG/M3,23KG/M3 | ||||||||||

| Technical Parameters | |||||||||||

| Model | QP-393E | ||||||||||

| Power supply | 220V 50HZ | ||||||||||

| Flow rate | 4.5KW | ||||||||||

| Working area | 1.5 M3 | ||||||||||

| Weight | 145kg(net weight of equipment) Work table (27kg) | ||||||||||

| Size(Equipment and work table) | 1.2m*0.9m*2.1m | ||||||||||

| Operating Temp/Hum | Temperature: -8℃-45℃, humidity: 5%-90% | ||||||||||

| Injection time | Adjustable | ||||||||||

System introduction

Client’s site installation picture

Perfect Product Protection Cost-effective Packaging Solution

In industrial,our products protect your products during the shipping, distribution, storage and selling cycles.

We provide customer-driven solutions through:

1. Consultative services and support in the whole word.

2. Technology and market expertise to solve your business challenges.

3. Cooperation with BASF ensure consistent product quality and service support in the industry

4. Cost-effective packaging that delivers measurable economic benefit.

5. The best training and support services in the industry to ensure you are ours products effective and economically,right from the start.

We have integrated common strengths,combined resources and created efficiencies to provide our customer with working solutions and real value.

Product detail pictures:

Related Product Guide:

All we do is always associated with our tenet Customer first, Trust first, devoting on the food packaging and environmental protection for Manufacturing Companies for Instapak 901 - polyurethane foam injection molding machine – Zhuangzhi , The product will supply to all over the world, such as: Liverpool, Barcelona, Benin, Our product quality is one of the major concerns and has been produced to meet the customer's standards. Customer services and relationship is another important area which we understand good communication and relationships with our customers is significant power to run it as a long term business.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.